NV-Explore at Dounreay

An innovative real-time radiation sensor deployed on a mobile robot into a contaminated nuclear fuel cell not accessed in over 25 years uncovers vital safety insights for workers at Dounreay.

The Challenge

An evaporator cell at Dounreay, which when operational was used to make pure water from salt water, had remained sealed for over 25 years. This resulted in its contamination and radiation dose rate being unknown to both Dounreay and our internal project team.

The complexity of this deployment was extremely advanced, not only due to the high levels of radiation but also because the team was guiding the robot into an area where the current condition was unknown. This meant initial surveys to gather insight into the state of the cell were essential in ensuring human operators could safely enter.

Moreover, restricted access between levels, narrow walkways, and poor lighting posed additional challenges. Sole access to levels beyond the ground floor relied on steep staircases within the cell.

A lack of information on the contamination and dose rates within the cell presented an obstacle to the nuclear decommissioning process, requiring a comprehensive understanding of the cell’s condition before any work could commence.

Our Solution

Our team tackled the challenges of the sealed Dounreay Cell by deploying our N-Visage Explore system. NV-Explore is our innovative payload, designed with advanced radiation characterisation algorithms. It uses precise radiation detection capabilities crucial for navigating hazardous environments.

Integrated with the Boston Dynamics Spot robot, NV-Explore facilitated exploration by providing high-quality 3D radiometric survey data across varying dose rates. The team operated Spot outside of the cell in a safe environment.

This solution involved deploying two Spot robots equipped with customised payloads. One Spot, equipped with NV-Explore, conducted thorough radiometric surveys throughout the cell, generating a detailed 3D reconstruction of radiation sources and dose planes.

Meanwhile, the second Spot performed supporting tasks, such as deploying Rajant mesh network nodes – devices used to extend and enhance communication networks – and conducting hardware inspections.

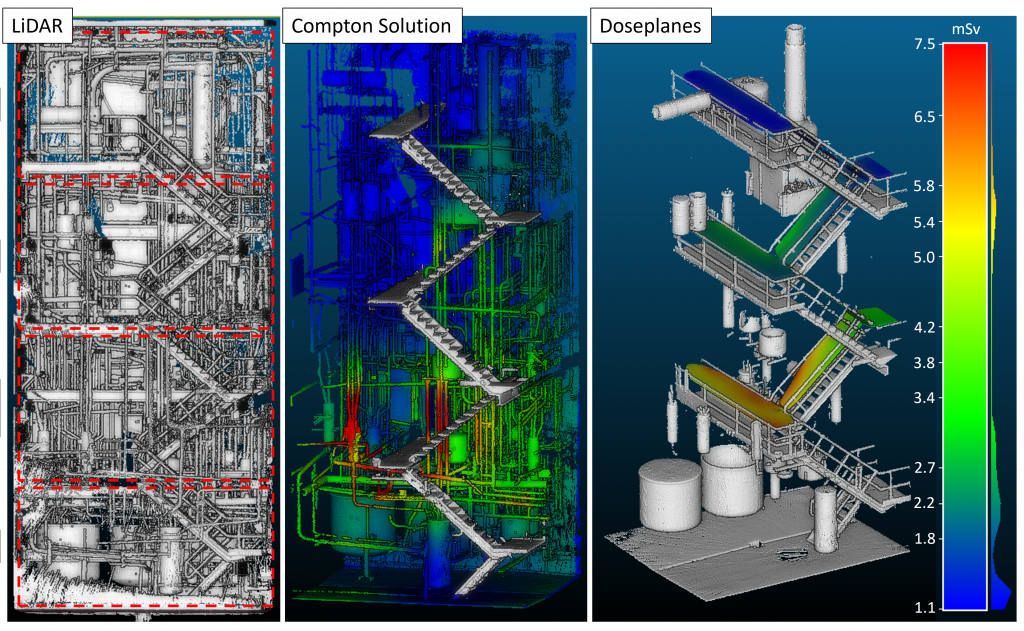

We partnered with Leica Geosystems to utilise the Leica BLKARC Lidar, which is capable of producing high-fidelity geospatial surveys, in the form of 3D pointclouds. These point clouds are used by NV-Explore both in an online survey format and post-processing format.

Through data analysis and post-processing, we established a clear understanding of the radiation distribution within the cell. This integrated approach not only addressed immediate challenges but also laid a foundation for scalable and efficient radiation characterisation in similar environments.

In addition to the innovative technology used in this deployment, both Spot robots were equipped with our new Robotic Protective Suit. This suit, expertly designed for robots like Boston Dynamics’ Spot, enables navigation and operation in the most challenging and hazardous conditions, preventing costly damage. Using these suits allowed us to navigate the highly contaminated cell, retrieve the robots, and swiftly redeploy them after thorough cleaning. This streamlined process not only saved time but also reduced costs and waste for our customer as the robots were able to stay in the environment and therefore each used only one suit for the week-long deployment, where human workers would require one per entry into the cell.

The Results

Using Boston Dynamics Spot robots equipped with NV-Explore, we successfully conducted radiometric survey missions throughout the cell, generating a comprehensive digital model of the environment.

The data gathered by our NV-Explore payload, allowed us to create a detailed 3D reconstruction of radiation sources and dose planes within the cell. Dose planes allow sites to model the amount of radiation absorbed at any point within in the modelled space, helping to inform plans about accessing the environment, such as where to place shielding and required PPE. Our team commenced operations on a Monday and concluded deployment by the end of the working week; meaning what traditionally would have been a much more time-consuming and costly endeavour was accomplished in only five days.

Results revealed varying dose rates ranging from 500 uSv/hr to 22 mSv/hr, which are classed as above safe working levels, across different areas of the cells. This detailed data not only provided crucial insights into the contamination and radiation levels within the cell but also enabled effective planning for the nuclear decommissioning process.

Read more of our insights...

Createc Partners with Curtiss-Wright to Drive Innovation in the U.S. Nuclear Sector

Createc Partners with Curtiss-Wright to Drive Innovation in the U.S. Nuclear Sector We’re delighted to…

Createc Joins Forces with Cognite and Aker Solutions to Launch Innovative Robot Garden

Createc Joins Forces with Cognite and Aker Solutions to Launch Innovative Robot Garden We’re excited…

Innovative Robotics Partnership Enhances Safety at Equinor’s Mongstad Facility

Innovative Robotics Partnership Enhances Safety at Equinor’s Mongstad Facility Developed with Cognite and Adigo, the…